2312 月

Double roller press granulation lines: How to overcome fertilizer granulation challenges?

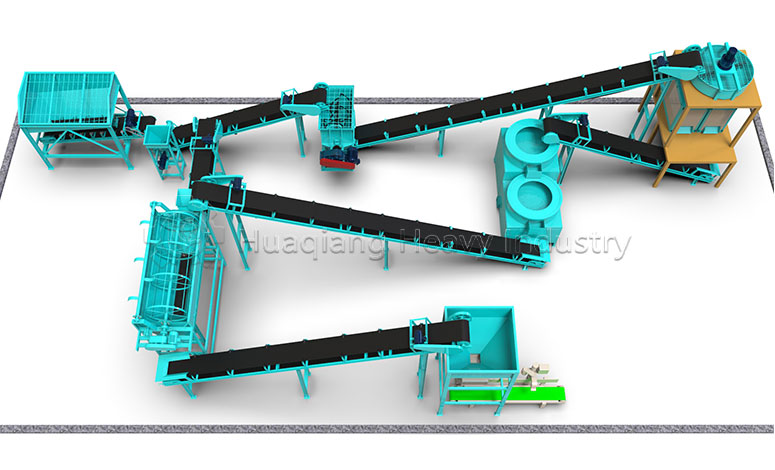

In the fertilizer granulation field, double roller press granulation lines, with their unique advantages of requiring no drying and low energy consumption, have become a key solution to the granulation challenges of high-moisture and heat-sensitive raw materials. Rather than operating as a single piece of equipment, they work in conjunction with multiple fertilizer equipment types to directly compress powdered raw materials into granules, opening up a new and efficient path for fertilizer production.

After the double roller press granulation production line starts, the raw materials first enter a vibration screener machine, which, like a "fine screening," removes impurities and large lumps, ensuring uniform particle size and laying the foundation for subsequent granulation. Next, qualified raw materials are conveyed to a double axis mixer. If the raw materials have uneven moisture or composition, the mixer can add a small amount of auxiliary materials and thoroughly mix them to achieve more stable material properties.

The core process is led by a double-roller extrusion granulator. Its two steel rollers rotate against each other, forcibly squeezing the incoming material into thin flakes. The material is then crushed by a crushing mechanism, and a drum screener selects the granules that meet the specifications. Unqualified granules are returned to the mixing stage, achieving zero raw material waste. The entire granulation process does not require high-temperature drying, which not only saves energy but also preserves volatile nutrients in the fertilizer. It is particularly suitable for the production of heat-sensitive fertilizers such as organic fertilizers and bio-fertilizers.

The production line is also equipped with an automatic quantitative packaging machine and a belt conveyor. After granulation, qualified granules are conveyed via a conveyor to a packaging machine, where they are precisely packaged into standard bags weighing 25-50 kg. This fully automated process reduces manual intervention and improves packaging efficiency and accuracy.

Compared to traditional granulation lines, the double-roll extrusion granulation line eliminates the need for a drying step, reduces energy consumption by over 30%, and can accommodate a wide range of raw materials.

The core process is led by a double-roller extrusion granulator. Its two steel rollers rotate against each other, forcibly squeezing the incoming material into thin flakes. The material is then crushed by a crushing mechanism, and a drum screener selects the granules that meet the specifications. Unqualified granules are returned to the mixing stage, achieving zero raw material waste. The entire granulation process does not require high-temperature drying, which not only saves energy but also preserves volatile nutrients in the fertilizer. It is particularly suitable for the production of heat-sensitive fertilizers such as organic fertilizers and bio-fertilizers.

The production line is also equipped with an automatic quantitative packaging machine and a belt conveyor. After granulation, qualified granules are conveyed via a conveyor to a packaging machine, where they are precisely packaged into standard bags weighing 25-50 kg. This fully automated process reduces manual intervention and improves packaging efficiency and accuracy.

Compared to traditional granulation lines, the double-roll extrusion granulation line eliminates the need for a drying step, reduces energy consumption by over 30%, and can accommodate a wide range of raw materials.

The core process is led by a double-roller extrusion granulator. Its two steel rollers rotate against each other, forcibly squeezing the incoming material into thin flakes. The material is then crushed by a crushing mechanism, and a drum screener selects the granules that meet the specifications. Unqualified granules are returned to the mixing stage, achieving zero raw material waste. The entire granulation process does not require high-temperature drying, which not only saves energy but also preserves volatile nutrients in the fertilizer. It is particularly suitable for the production of heat-sensitive fertilizers such as organic fertilizers and bio-fertilizers.

The production line is also equipped with an automatic quantitative packaging machine and a belt conveyor. After granulation, qualified granules are conveyed via a conveyor to a packaging machine, where they are precisely packaged into standard bags weighing 25-50 kg. This fully automated process reduces manual intervention and improves packaging efficiency and accuracy.

Compared to traditional granulation lines, the double-roll extrusion granulation line eliminates the need for a drying step, reduces energy consumption by over 30%, and can accommodate a wide range of raw materials.

The core process is led by a double-roller extrusion granulator. Its two steel rollers rotate against each other, forcibly squeezing the incoming material into thin flakes. The material is then crushed by a crushing mechanism, and a drum screener selects the granules that meet the specifications. Unqualified granules are returned to the mixing stage, achieving zero raw material waste. The entire granulation process does not require high-temperature drying, which not only saves energy but also preserves volatile nutrients in the fertilizer. It is particularly suitable for the production of heat-sensitive fertilizers such as organic fertilizers and bio-fertilizers.

The production line is also equipped with an automatic quantitative packaging machine and a belt conveyor. After granulation, qualified granules are conveyed via a conveyor to a packaging machine, where they are precisely packaged into standard bags weighing 25-50 kg. This fully automated process reduces manual intervention and improves packaging efficiency and accuracy.

Compared to traditional granulation lines, the double-roll extrusion granulation line eliminates the need for a drying step, reduces energy consumption by over 30%, and can accommodate a wide range of raw materials. All Categories

Tags

belt conveyor

Bucket Elevator

cage crusher

Chain crusher

disc granulator

disc granulator machine

disc granulators

double-roll extrusion granulator

double axis mixer

double roller press granulator

drum fertilizer dryer

drum granulator

fertilizer crusher

fertilizer equipment

fertilizer granulator

fertilizer production line

fertilizer rotary screener machine

flat die pelleting machine

Flat Die Pellet Machines

half-wet material crusher

Health

horizontal mixer

Insurance

large wheel compost turner

large wheel compost turning machine

Life

new type two-in-one organic fertilizer granulator

NPK compound fertilizer production line

NPK fertilizer production line

NPK fertilizer production lines

organic fertilizer production lines

organic fertilizer production line

Policy

Protect

Ring Die Pelleting Machine

roller extrusion granulators

Rotary drum granulators

rotary drum granulator

rotary screener machine

Safe

twin-shaft mixer

vertical disc mixer

vertical dis mixer

vibration screener machine

windrow compost turner

MON-SAT 8:00-9:00

+91 69 863 6420