062 月

Scientific Formulation of Three Major Nutrients: The Precise Synergy of N-P-K

Common NPK Formulations and Applications

General-Purpose Balanced Formulations

15-15-15: Balanced nutrition suitable for most field crops

17-17-17: High-concentration balanced fertilizer suitable for cash crops

20-20-20: Fully water-soluble formulation suitable for drip and spray irrigation

Specialized Crop Formulations

Corn-specific fertilizer: 28-6-6, high nitrogen for growth promotion

Fruit tree-specific fertilizer: 15-15-20, high potassium for quality improvement

Vegetable-specific fertilizer: 20-10-20, balanced for high yield

Functional Specialty Formulations

Slow-release fertilizers: Added controlled-release materials to extend fertilizer efficiency

Bio-fertilizers: Compound microbial agents to improve soil

Medium/trace element fertilizers: Added calcium, magnesium, sulfur, zinc, boron, etc.

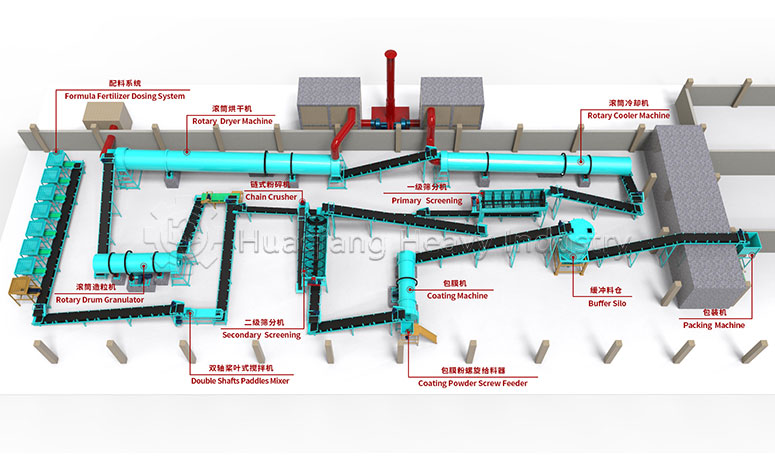

NPK Production Line Technical Parameters

NPK Production Line Technical Parameters

Core Advantages of Modern NPK Production Lines

Precise Nutrient Control

Efficient Resource Utilization

Flexible Production Capacity

Excellent Product Quality

Environmentally Friendly Process

Intelligent Control System

Quick Changeover Capability

Low Maintenance High Reliability

Precise Nutrient Control: Computer control systems ensure accurate proportioning of various nutrient elements with errors less than 1%. Online detection systems monitor product quality in real time, automatically adjusting process parameters.

Efficient Resource Utilization: Closed-loop circulation design achieves over 99% raw material utilization, with energy consumption 30-40% lower than traditional processes. Zero wastewater discharge, dust emissions below national standards.

Flexible Production Capacity: Quick changeover systems can complete formulation switching within 30 minutes, adapting to multi-variety, small-batch market demands. From general-purpose to specialized fertilizers, one machine serves multiple functions.

Excellent Product Quality: High granule uniformity (≥95%), moderate strength (15-30N), controllable dissolution characteristics. Nutrients release uniformly in soil, with lasting and stable fertilizer efficiency.

Intelligent Control System Configuration

Modern NPK fertilizer production lines are equipped with advanced intelligent control systems, achieving comprehensive automation of the production process:

Central Control Room: Integrates monitoring and control of all equipment, with rotary screener machine displaying real-time production data. Operators can manage the entire production line through touchscreens.

PLC Automatic Control: Programmable logic controllers achieve equipment linkage and automatic operation. Formula management systems can store hundreds of formulations for one-click calling.

Online Quality Detection: Near-infrared spectrometers detect product nutrient content in real time, while laser particle size analyzers monitor granule size distribution. Data is fed back to the control system in real time.

Data Collection and Traceability: Production data automatically recorded and stored, achieving full traceability from raw materials to finished products. Each batch of products has complete quality files.

Remote Monitoring and Maintenance: machinery and granulation technology enables remote equipment monitoring, with expert systems providing maintenance suggestions. Predictive maintenance reduces unplanned downtime.

Wide Application Fields

Products from NPK fertilizer production lines are widely used in various fields of modern agriculture:

Field Crop Production: Nutritional supply for main grain crops like wheat, rice, corn, and soybeans. Provides specialized formula fertilizers according to nutritional needs at different growth stages.

Cash Crop Cultivation: Precise fertilization for cash crops like fruit trees, vegetables, cotton, tobacco, and tea. High-potassium formulations improve fruit quality, high-nitrogen formulations promote vegetative growth.

Facility Agriculture Applications: Integrated water and fertilizer systems for facility agriculture like greenhouses and plastic tunnels. Fully water-soluble formulations suitable for drip and spray irrigation systems, improving fertilizer utilization.

Landscape Maintenance: Maintenance management for urban greening, golf courses, and sports field turf. Slow-release formulations reduce fertilization frequency, lowering maintenance costs.

Special Agricultural Needs: Special requirements for organic agriculture, ecological agriculture, and precision agriculture. Adding functional materials like biostimulants and soil amendments.

Future Development Trends

With the deepening of precision agriculture and sustainable development concepts, NPK fertilizer production lines are developing in the following directions:

Customized Services: Provide personalized formulations based on soil test data and crop needs. Full technical support from laboratory trials to industrial production. Produce on demand, reducing inventory pressure.

The NPK fertilizer production line is an important component of modern agricultural production systems. It transforms scientific nutritional formulations into industrialized products, providing solid guarantees for global food security and agricultural sustainable development. With continuous technological advancement, this production line will become more intelligent, efficient, and environmentally friendly, injecting new vitality into the development of precision agriculture and green agriculture.

NPK Production Line Technical Parameters

NPK Production Line Technical Parameters

| Parameter Category | Small Production Line | Medium Production Line | Large Production Line |

| Design Capacity | 3-5 tons/hour | 5-15 tons/hour | 15-30 tons/hour |

| Annual Production Capacity | 10,000-20,000 tons | 30,000-50,000 tons | 50,000-100,000 tons |

| Total Installed Power | 150-300kW | 300-600kW | 600-1200kW |

| Floor Space | 800-1500m² | 1500-3000m² | 3000-6000m² |

| Operating Personnel | 6-8 people/shift | 8-12 people/shift | 12-16 people/shift |

| Automation Level | 80-85% | 85-90% | 90-95% |

All Categories

Tags

BB fertilizer mixers

belt conveyor

cage crusher

Chain crusher

chain crushers

disc granulator

disc granulator machine

disc graulator

double axis mixer

double screws compost turner

double roller press granulation production line

double roller press granulator

Double roller press granulators

drum fertilizer dryer

drum granulator

fertilizer equipment

fertilizer production

fertilizer production line

fertilizer rotary screener machine

flat die pelleting machine

Flat Die Pellet Machines

half-wet material crusher

Health

horizontal mixer

Insurance

large wheel compost turner

large wheel compost turning machine

Life

new type organic fertilizer granulator

new type two-in-one organic fertilizer granulator

NPK fertilizer production lines

oil palm empty fruit bunches

oil palm empty fruit bunches (OPEFB)

organic fertilizer production lines

organic fertilizer production line

Policy

Protect

Ring Die Pelleting Machine

rotary drum granulator

rotary screener machine

Safe

simple compost turning machine

vertical disc mixer

vertical dis mixer

vibration screener machine

MON-SAT 8:00-9:00

+91 69 863 6420