3012 月

Organic Fertilizer Production Lines: How Do They Contribute to Green Agriculture?

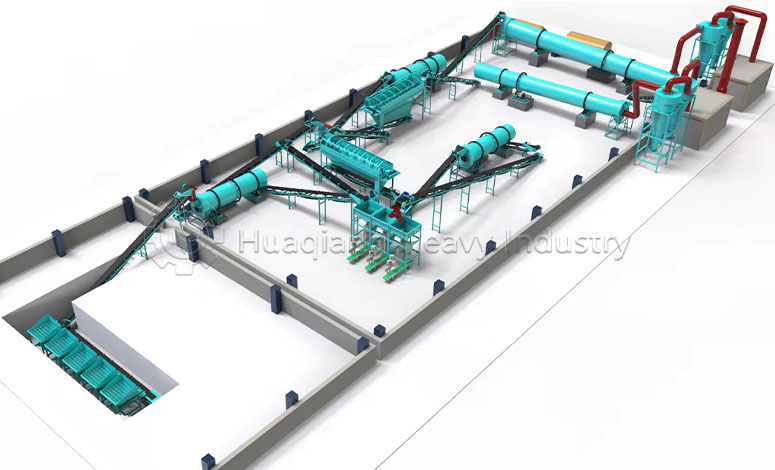

Amid the global push for sustainable agriculture, organic fertilizer production lines are becoming a crucial bridge connecting agricultural waste and sustainable farming. This system is more than a simple combination of individual pieces of equipment; it encompasses a comprehensive solution encompassing raw material processing, fermentation, composting, and further processing. It also cleverly integrates a variety of auxiliary fertilizer equipment to create an efficient and environmentally friendly closed-loop fertilizer production cycle.

The organic fertilizer production line begins with the meticulous selection of raw material pretreatment equipment. A pulverizer breaks raw materials like straw and livestock manure into uniform particles, while a rotary screener machine removes impurities, laying the foundation for subsequent fermentation.Next, the fermentation turning machine enters the picture—the heart of the production line. Regularly turning the raw materials allows them to fully air out, accelerating microbial decomposition. In just a few weeks, the waste is transformed into pre-composted organic fertilizer. If compound fertilizer is needed, the compound fertilizer mixer precisely adds nitrogen, phosphorus, potassium, and other elements to meet the nutritional needs of different crops.

The further processing stages are equally impressive. The new type two in one organic fertilizer granulator forms composted materials into granules for easy storage and application, while the dryer quickly removes excess moisture to ensure the fertilizer's shelf life. Finally, the packaging machine automatically weighs and seals the finished bags of high-quality organic fertilizer.Notably, the exhaust gas treatment equipment installed throughout the production line effectively filters odors generated during the fermentation process, achieving "zero-pollution" production.

From agricultural waste to high-quality fertilizer, the organic fertilizer production line not only solves environmental challenges but also provides natural nutrients to the soil. The organic fertilizer it produces improves soil structure, enhances crop quality, and, when used in conjunction with chemical fertilizers, reduces residual fertilizer residue.

The further processing stages are equally impressive. The new type two in one organic fertilizer granulator forms composted materials into granules for easy storage and application, while the dryer quickly removes excess moisture to ensure the fertilizer's shelf life. Finally, the packaging machine automatically weighs and seals the finished bags of high-quality organic fertilizer.Notably, the exhaust gas treatment equipment installed throughout the production line effectively filters odors generated during the fermentation process, achieving "zero-pollution" production.

From agricultural waste to high-quality fertilizer, the organic fertilizer production line not only solves environmental challenges but also provides natural nutrients to the soil. The organic fertilizer it produces improves soil structure, enhances crop quality, and, when used in conjunction with chemical fertilizers, reduces residual fertilizer residue.

The further processing stages are equally impressive. The new type two in one organic fertilizer granulator forms composted materials into granules for easy storage and application, while the dryer quickly removes excess moisture to ensure the fertilizer's shelf life. Finally, the packaging machine automatically weighs and seals the finished bags of high-quality organic fertilizer.Notably, the exhaust gas treatment equipment installed throughout the production line effectively filters odors generated during the fermentation process, achieving "zero-pollution" production.

From agricultural waste to high-quality fertilizer, the organic fertilizer production line not only solves environmental challenges but also provides natural nutrients to the soil. The organic fertilizer it produces improves soil structure, enhances crop quality, and, when used in conjunction with chemical fertilizers, reduces residual fertilizer residue.

The further processing stages are equally impressive. The new type two in one organic fertilizer granulator forms composted materials into granules for easy storage and application, while the dryer quickly removes excess moisture to ensure the fertilizer's shelf life. Finally, the packaging machine automatically weighs and seals the finished bags of high-quality organic fertilizer.Notably, the exhaust gas treatment equipment installed throughout the production line effectively filters odors generated during the fermentation process, achieving "zero-pollution" production.

From agricultural waste to high-quality fertilizer, the organic fertilizer production line not only solves environmental challenges but also provides natural nutrients to the soil. The organic fertilizer it produces improves soil structure, enhances crop quality, and, when used in conjunction with chemical fertilizers, reduces residual fertilizer residue. All Categories

Tags

belt conveyor

Bucket Elevator

cage crusher

Chain crusher

disc granulator

disc granulator machine

disc granulators

double-roll extrusion granulator

double axis mixer

double roller press granulator

drum fertilizer dryer

drum granulator

fertilizer crusher

fertilizer equipment

fertilizer granulator

fertilizer production line

fertilizer rotary screener machine

flat die pelleting machine

Flat Die Pellet Machines

half-wet material crusher

Health

horizontal mixer

Insurance

large wheel compost turner

large wheel compost turning machine

Life

new type two-in-one organic fertilizer granulator

NPK compound fertilizer production line

NPK fertilizer production line

NPK fertilizer production lines

organic fertilizer production lines

organic fertilizer production line

Policy

Protect

Ring Die Pelleting Machine

roller extrusion granulators

Rotary drum granulators

rotary drum granulator

rotary screener machine

Safe

twin-shaft mixer

vertical disc mixer

vertical dis mixer

vibration screener machine

windrow compost turner

MON-SAT 8:00-9:00

+91 69 863 6420