062 月

Raw Material Adaptability and Flexible Proportioning Characteristics of NPK Fertilizer Production Lines

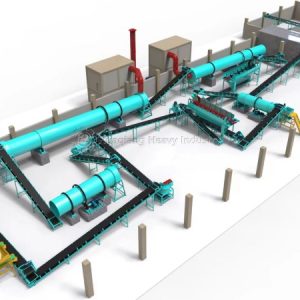

NPK fertilizer production lines are core equipment in the modern fertilizer industry, producing compound fertilizers with nitrogen (N), phosphorus (P), and potassium (K) as the main components to support crop growth. Their characteristics in fertilizer production are particularly evident in their raw material adaptability and flexible proportioning. First, strong raw material adaptability is a major advantage of NPK fertilizer production lines. The production line can process various raw materials, such as urea as a nitrogen source, synthesized from atmospheric nitrogen; ammonium phosphate as a phosphorus source; and potassium chloride as a potassium source. This diversity of raw materials allows the production line to adjust according to market and soil needs, avoiding the risk of reliance on a single raw material. At the same time, the fully automatic mixing system ensures uniform distribution of nutrients, preventing nutrient segregation. This not only improves the quality of the fertilizer but also supports customized production, adapting to the future trend of precision agriculture.

In terms of flexible proportioning, NPK fertilizer production lines allow for real-time adjustment of the N:P:K ratio based on soil tests and crop types. For example, high-nitrogen fertilizers can be produced for leafy vegetables; while high-phosphorus formulations are emphasized for root crops. This characteristic makes the production line suitable for different concentrations of compound fertilizers, such as the production of low-concentration fertilizers, meeting diverse market demands. The automated metering system has an accuracy of up to 1%, reducing human error and ensuring the consistency of each batch of fertilizer. In addition, the production line supports the addition of trace elements, such as zinc or boron, to form micronutrient compound products, further enhancing fertilizer efficiency.

The core of the production process is granulation technology, including extrusion granulation, tower granulation, and agglomeration. Extrusion granulation does not require additional drying and cooling, has a high granulation rate, and strong particle solidification, making it particularly suitable for low-concentration compound fertilizers. Tower granulation improves fluidity through emulsified slurry, preventing nozzle clogging and ensuring uniform particles. The agglomeration method has a simple processing flow, low investment, and quick start-up; although the particles are rough, they have high strength, facilitating storage and transportation. These technologies improve the physical properties of the fertilizer, such as solubility and slow-release properties, reducing nutrient loss during fertilization.

Drying and cooling processes are also important characteristics of NPK fertilizer production lines. The drying process uses high-efficiency dryers, such as rotary dryers, which can control particle humidity and size, and support dyeing to improve product appearance. Environmental design emphasizes energy recovery, utilizing waste heat to preheat raw materials and reduce electricity consumption. Despite the relatively high power consumption of the production process, modern production lines integrate wastewater treatment and dust removal systems, supporting green manufacturing. For example, a project producing 5,000 tons of organic fertilizer annually emphasizes environmental standards, ensuring emissions comply with regulations.

Automation and intelligent control further enhance the efficiency of NPK fertilizer production lines. Through PLC systems and AI monitoring, continuous production and high-capacity adjustments are achieved. The high capacity and flexibility of European factories ensure consistent product quality. Furthermore, the production line supports the addition of organic components or microorganisms to create bio-compound fertilizers, improving overall fertilizer efficiency. Overall, these characteristics of NPK fertilizer production lines make them a key tool for sustainable agricultural development, optimizing production processes, increasing crop yields, and reducing environmental impact.

The core of the production process is granulation technology, including extrusion granulation, tower granulation, and agglomeration. Extrusion granulation does not require additional drying and cooling, has a high granulation rate, and strong particle solidification, making it particularly suitable for low-concentration compound fertilizers. Tower granulation improves fluidity through emulsified slurry, preventing nozzle clogging and ensuring uniform particles. The agglomeration method has a simple processing flow, low investment, and quick start-up; although the particles are rough, they have high strength, facilitating storage and transportation. These technologies improve the physical properties of the fertilizer, such as solubility and slow-release properties, reducing nutrient loss during fertilization.

Drying and cooling processes are also important characteristics of NPK fertilizer production lines. The drying process uses high-efficiency dryers, such as rotary dryers, which can control particle humidity and size, and support dyeing to improve product appearance. Environmental design emphasizes energy recovery, utilizing waste heat to preheat raw materials and reduce electricity consumption. Despite the relatively high power consumption of the production process, modern production lines integrate wastewater treatment and dust removal systems, supporting green manufacturing. For example, a project producing 5,000 tons of organic fertilizer annually emphasizes environmental standards, ensuring emissions comply with regulations.

Automation and intelligent control further enhance the efficiency of NPK fertilizer production lines. Through PLC systems and AI monitoring, continuous production and high-capacity adjustments are achieved. The high capacity and flexibility of European factories ensure consistent product quality. Furthermore, the production line supports the addition of organic components or microorganisms to create bio-compound fertilizers, improving overall fertilizer efficiency. Overall, these characteristics of NPK fertilizer production lines make them a key tool for sustainable agricultural development, optimizing production processes, increasing crop yields, and reducing environmental impact.

The core of the production process is granulation technology, including extrusion granulation, tower granulation, and agglomeration. Extrusion granulation does not require additional drying and cooling, has a high granulation rate, and strong particle solidification, making it particularly suitable for low-concentration compound fertilizers. Tower granulation improves fluidity through emulsified slurry, preventing nozzle clogging and ensuring uniform particles. The agglomeration method has a simple processing flow, low investment, and quick start-up; although the particles are rough, they have high strength, facilitating storage and transportation. These technologies improve the physical properties of the fertilizer, such as solubility and slow-release properties, reducing nutrient loss during fertilization.

Drying and cooling processes are also important characteristics of NPK fertilizer production lines. The drying process uses high-efficiency dryers, such as rotary dryers, which can control particle humidity and size, and support dyeing to improve product appearance. Environmental design emphasizes energy recovery, utilizing waste heat to preheat raw materials and reduce electricity consumption. Despite the relatively high power consumption of the production process, modern production lines integrate wastewater treatment and dust removal systems, supporting green manufacturing. For example, a project producing 5,000 tons of organic fertilizer annually emphasizes environmental standards, ensuring emissions comply with regulations.

Automation and intelligent control further enhance the efficiency of NPK fertilizer production lines. Through PLC systems and AI monitoring, continuous production and high-capacity adjustments are achieved. The high capacity and flexibility of European factories ensure consistent product quality. Furthermore, the production line supports the addition of organic components or microorganisms to create bio-compound fertilizers, improving overall fertilizer efficiency. Overall, these characteristics of NPK fertilizer production lines make them a key tool for sustainable agricultural development, optimizing production processes, increasing crop yields, and reducing environmental impact.

The core of the production process is granulation technology, including extrusion granulation, tower granulation, and agglomeration. Extrusion granulation does not require additional drying and cooling, has a high granulation rate, and strong particle solidification, making it particularly suitable for low-concentration compound fertilizers. Tower granulation improves fluidity through emulsified slurry, preventing nozzle clogging and ensuring uniform particles. The agglomeration method has a simple processing flow, low investment, and quick start-up; although the particles are rough, they have high strength, facilitating storage and transportation. These technologies improve the physical properties of the fertilizer, such as solubility and slow-release properties, reducing nutrient loss during fertilization.

Drying and cooling processes are also important characteristics of NPK fertilizer production lines. The drying process uses high-efficiency dryers, such as rotary dryers, which can control particle humidity and size, and support dyeing to improve product appearance. Environmental design emphasizes energy recovery, utilizing waste heat to preheat raw materials and reduce electricity consumption. Despite the relatively high power consumption of the production process, modern production lines integrate wastewater treatment and dust removal systems, supporting green manufacturing. For example, a project producing 5,000 tons of organic fertilizer annually emphasizes environmental standards, ensuring emissions comply with regulations.

Automation and intelligent control further enhance the efficiency of NPK fertilizer production lines. Through PLC systems and AI monitoring, continuous production and high-capacity adjustments are achieved. The high capacity and flexibility of European factories ensure consistent product quality. Furthermore, the production line supports the addition of organic components or microorganisms to create bio-compound fertilizers, improving overall fertilizer efficiency. Overall, these characteristics of NPK fertilizer production lines make them a key tool for sustainable agricultural development, optimizing production processes, increasing crop yields, and reducing environmental impact. All Categories

Tags

BB fertilizer mixers

belt conveyor

cage crusher

Chain crusher

chain crushers

disc granulator

disc granulator machine

disc graulator

double axis mixer

double screws compost turner

double roller press granulation production line

double roller press granulator

Double roller press granulators

drum fertilizer dryer

drum granulator

fertilizer equipment

fertilizer production

fertilizer production line

fertilizer rotary screener machine

flat die pelleting machine

Flat Die Pellet Machines

half-wet material crusher

Health

horizontal mixer

Insurance

large wheel compost turner

large wheel compost turning machine

Life

new type organic fertilizer granulator

new type two-in-one organic fertilizer granulator

NPK fertilizer production lines

oil palm empty fruit bunches

oil palm empty fruit bunches (OPEFB)

organic fertilizer production lines

organic fertilizer production line

Policy

Protect

Ring Die Pelleting Machine

rotary drum granulator

rotary screener machine

Safe

simple compost turning machine

vertical disc mixer

vertical dis mixer

vibration screener machine

MON-SAT 8:00-9:00

+91 69 863 6420